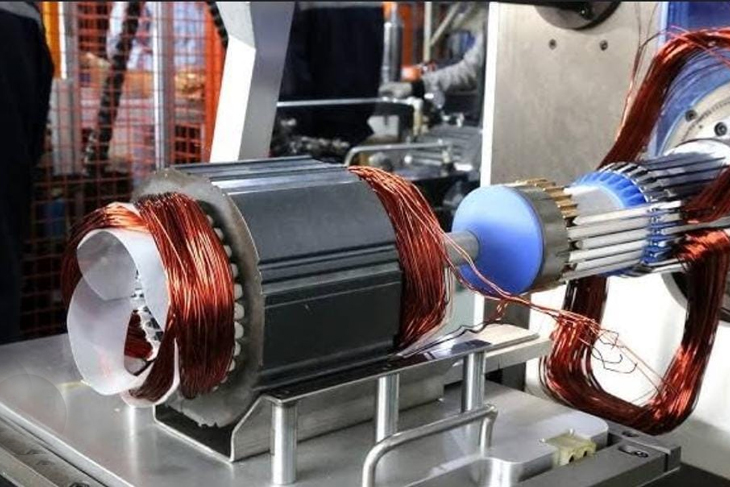

Compressor Stator Rewinding

We specialize in compressor stator rewinding, helping extend the life of your compressor motors, reduce downtime, and restore optimal performance. Whether you're dealing with a single-phase or three-phase motor, our team delivers precision rewinding using high-quality materials and the latest techniques.

Compressor stator rewinding is carried out by removing the damaged or burned-out coil windings from the stator of an electric motor and replacing them with new wire windings. This is a critical repair that brings back the original performance and efficiency of the motor without needing a full replacement.

Types of Rewinding We Offer

-

Single-Phase Rewinding

Three-Phase Rewinding

Lap Winding

Wave Winding

Formed Coil Rewinding

Random Winding (Mush Winding)

Wire Gauges Used in Stator Rewinding

Selecting the right wire gauge is crucial for performance, thermal stability, and current handling. We use high-grade enameled copper or aluminum wire, based on the motor specifications.

Small Compressors (0.5 HP – 2 HP):

- Gauge: SWG 28 to SWG 22 (or AWG 18 to AWG 14)

- Commonly used in HVAC, refrigeration, and portable compressors.

- Gauge: SWG 20 to SWG 16 (or AWG 14 to AWG 10)

- Used in workshops, small industries, and construction tools.

- Gauge: SWG 16 to SWG 10 (or AWG 10 to AWG 6)

- Handles high voltage/current requirements with advanced insulation techniques.

If your compressor is losing efficiency, showing signs of overheating, or has stopped working, our rewinding service can save you from costly replacements